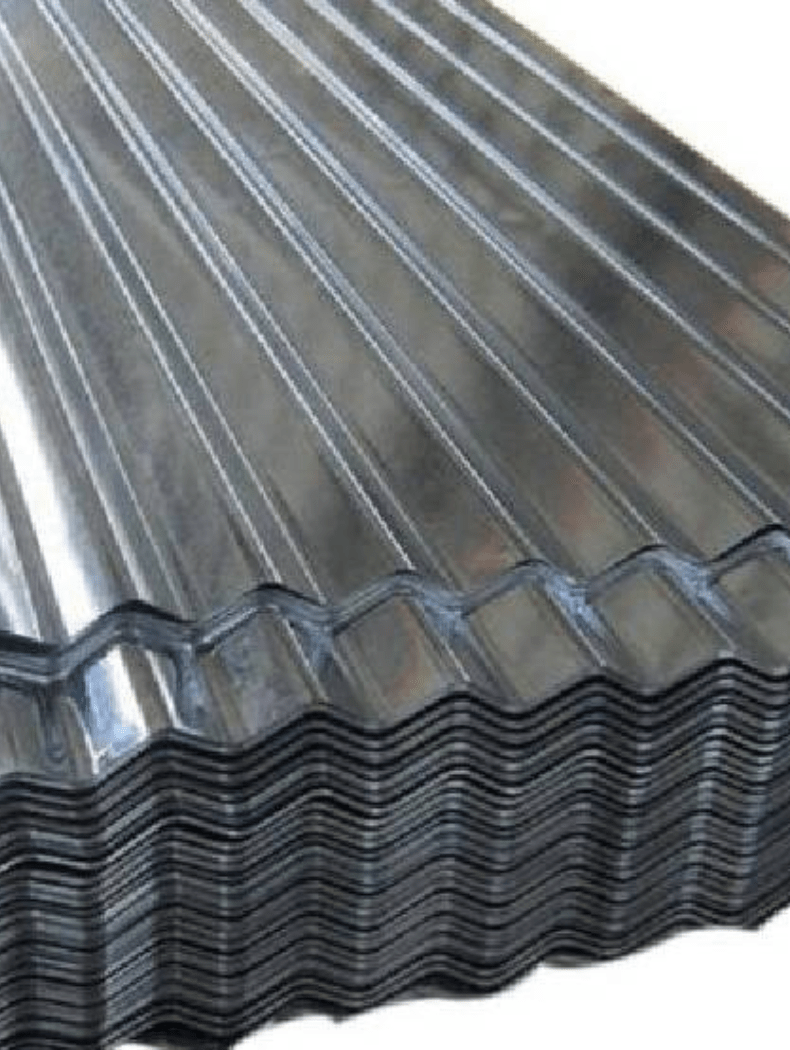

GP Sheet

GP sheets, or Galvanized Plain sheets, are similar to GI sheets in that they are also coated with a layer of zinc for corrosion resistance.

GP sheet are compatible with different construction methods and can be easily customised to fit specific requirements

GP sheets are commonly used in various applications such as roofing, cladding, and general fabrication. GP sheets, or Galvanized Plain sheets, have a wide range of common applications. It is used for roofing in residential, commercial, and industrial buildings due to their durability and corrosion resistance. GP sheets are also used in the construction of walls, partitions, and ceilings. Additionally, they find applications in the manufacturing of gutters, ducts, and electrical enclosures. Their versatility and strength make them suitable for various industries, including agriculture, automotive, and infrastructure.

GP sheets provide protection against corrosion and can withstand harsh industrial environments. They are also used for manufacturing air ducts, equipment enclosures, and storage tanks. Additionally, GP sheets are utilized in the construction of platforms, walkways, and mezzanines.

The main difference is that GP sheets do not have a specific spangled pattern on the surface like GI sheets do. They offer similar advantages as GI sheets, including:-Easy Maintenance: GP sheets require minimal maintenance, reducing the overall maintenance costs over time,Cost-Effective: GP sheets are generally affordable compared to other roofing and construction materials, offering value for money. Durability: They can withstand harsh weather conditions and are resistant to rust and other forms of degradation. Corrosion Resistance: The zinc coating on GP sheets provides excellent protection against corrosion, making them suitable for outdoor applications.

Their durability, cost-effectiveness, and versatility make them a popular choice in industrial applications.