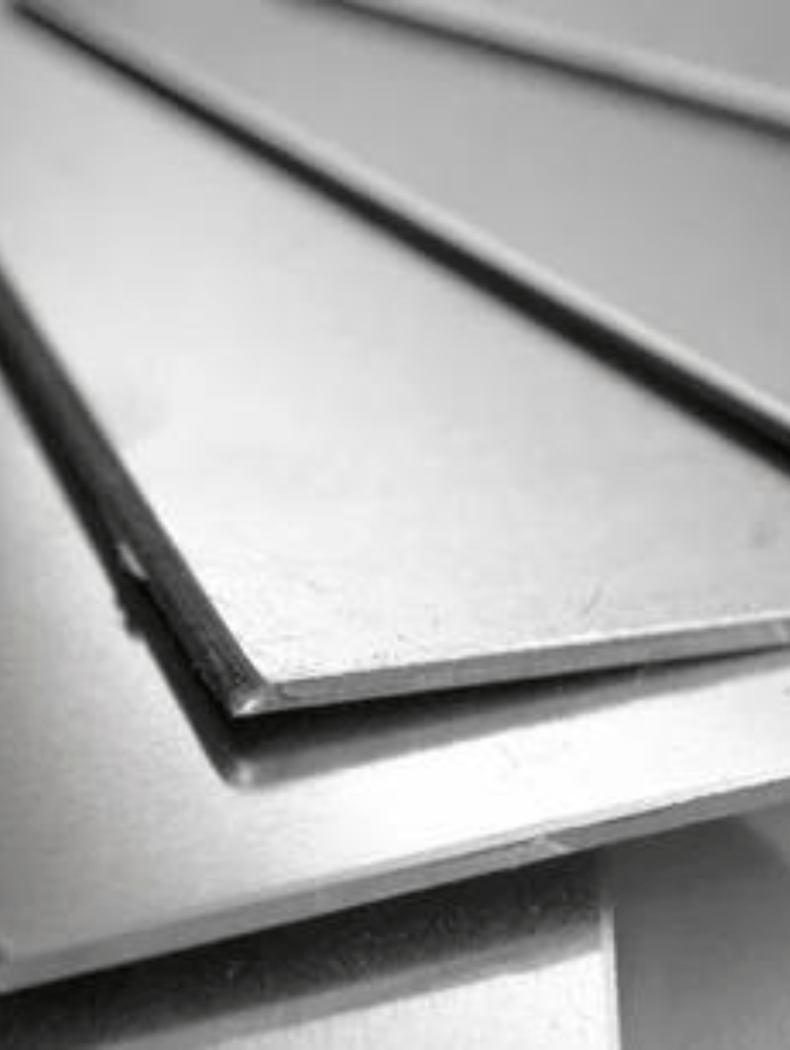

CR Sheet

CR sheet, which stands for Cold Rolled sheet, is another type of steel product used widely in various industries. Unlike HR sheets, which are produced at high temperatures, CR sheets are made at room temperature through a process called cold rolling.

During the cold rolling process, cooled hot rolled steel passes through another series of rollers at room temperature. Since the material is no longer hot and malleable. a significantly higher amount of pressure is required to compress it into the desired shape

Let’s break it down in simple terms:

Imagine you have a big block of steel, but instead of heating it up, you keep it at room temperature. Then, you squeeze it between rollers to make it thinner and longer. That’s how CR sheets are made – without the heat.

Because they’re made at room temperature, CR sheets have a smoother surface compared to HR sheets. They don’t have that scale layer you find on HR sheets. This smoothness makes CR sheets great for applications where appearance matters, like making shiny metal parts or surfaces.

They’re often used in things like appliances, furniture, and even in some types of construction where a smooth finish is needed.

One of the biggest advantages of CR sheets is their versatility. They can be easily manipulated into different shapes without losing their strength. This makes them a go-to choice for manufacturers who need flexibility in their designs.

Despite not being as strong as HR sheets, they’re still widely used in many industries for their versatility and ease of manipulation.