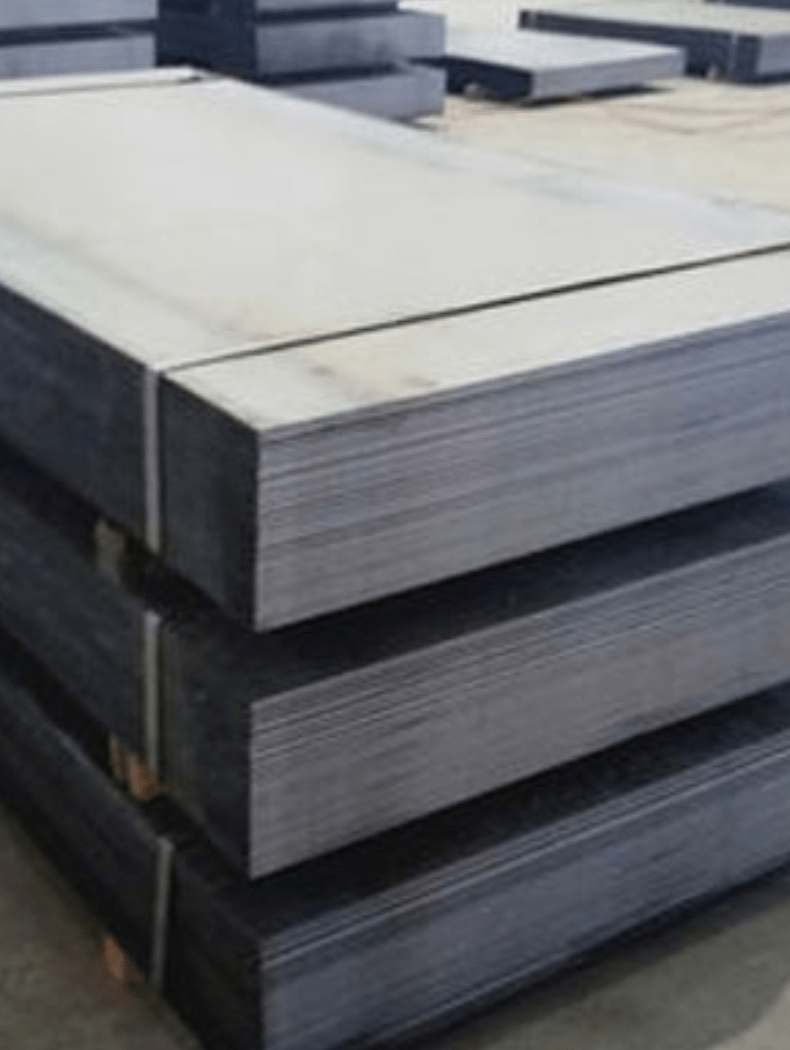

HR Sheet

HR sheet, short for Hot Rolled sheet, is a kind of steel made by heating a big chunk of metal and rolling it out while it’s still hot. This process helps shape the metal into thin sheets.

It is used as a raw material that can be easily transformed into different dimensions

Hot roll steel is rolled above the material’s re crystallization temperature , The processed material exhibits greater formability and workability, making it easier to work with in subsequent processing operations.

Imagine you have a big, hot lump of metal. You squash it between rollers until it becomes a long, flat sheet. That’s basically how HR sheets are made. Because they’re rolled out when the metal is hot, they end up having a layer of scale on the surface, kind of like a protective coating. This scale helps stop the metal from getting rusty.

The best part about HR sheets is that they’re cheaper to make compared to some other types of steel sheets. That’s because the process to make them doesn’t require as much fancy equipment. So, they’re a good choice when you need a lot of strong metal without spending a ton of money.

Hot rolled steel offers several manufacturing advantages, such as:

- Lower cost: Hot rolled steel tends to be less expensive than cold rolled steel since it involves less processing

- Better workability: As the hot rolling process occurs at elevated temperatures, the processed material is easy to form and shape.

-

Little to no internal stress: The hot rolling process involves cooling the steel gradually, which allows the material to essentially normalize its structure and become free of internal stresses